The Gelcoater

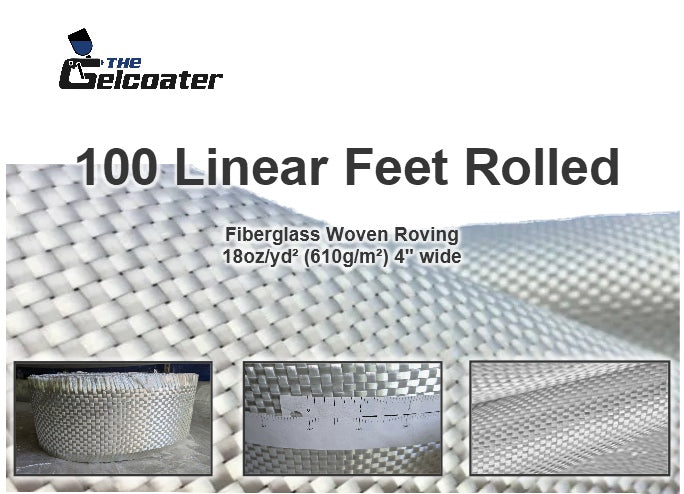

100 Feet of 4" wide, 18oz/yd² (610g/m²), Fiberglass Woven Roving

100 Feet of 4" wide, 18oz/yd² (610g/m²), Fiberglass Woven Roving

Couldn't load pickup availability

The Gelcoater Multi Compatible Fiberglass Woven Roving is a premium quality woven roving that is compatible with Polyester, Vinyl ester and Epoxy Resin Systems. This woven roving is a great way to quickly and economically build up and add strength to your project or repair. It also wets out faster and more evenly to accelerate rolling and brushing. The high quality of this fabric ensures uniform weight and construction minimizing the potential for air entrapment and weak areas in the laminate which helps produce stronger, smoother parts.

While our woven roving is multi-compatible it should be noted that if it is being used in conjunction with (CSM) chopped strand mat (as is often the case), only polyester or vinyl ester resin should be used. This is because the binder in CSM is only compatible with polyester and vinyl ester resins therefor adjacent laminates must be compatible with these.

The Gelcoater Woven Roving has higher mechanical properties (modulous of elasticity) than regular plain weave E-glass cloth but due to its heavier weight, is not as suitable for conforming to complex shapes as cloth. In simple terms, woven roving is more stiff than and will resist non-permanent deformation better than regular cloth but because of this stiffness it will not drape as easily and is more suited to flat and simple curves than regular cloth.

Typical uses of woven roving include boat and marine production, aerospace and automotive parts, container and corrosion-resistant tank construction, composite construction and repair, home furnishings, sports equipment, translucent panels, concrete forms and other parts/panels with large areas.

NOTE: The width of the woven strands (warp and weft) between the 2 selvedge ends is 4 inches but if you include the unwoven weft ends on the outsides of the selvedge, the width is 5 to 6 inches.

Features:

- 18oz/yd² (610g/m²) woven roving has the right combination of fabric weight, thickness and construction to economically and rapidly build up areas that require high strength reinforcement.

- Uniform weight and construction minimize the potential for air entrapment and weak areas in the laminate. This helps produce stronger, smoother parts.

- Has higher mechanical properties (strength and stiffness) than fiberglass cloth.

- Wets out faster and more evenly to accelerate rolling and brushing.

- Advantages in reducing costs and contributing to end-product quality.

- Reduced fabrication time.

- Compatible with Polyester, Vinyl ester and Epoxy Resin Systems.

Specifications:

| Coating: | Silane |

| Yarn Linear Density (TEX/Yield): | Weft: 1200/413 |

| Warp: 1200/413 | |

| Filament Diameter (μm): | Warp: 17 |

| Weft: 17 | |

| Counts (ends/inch): | Warp: 6.4 |

| Weft: 6.4 | |

| Yarn orientation (angle): | Warp: 0 degrees |

| Weft: 90 degrees | |

| Total Width (including weft outside of selvedge): | 5-6 inches |

| Woven Width (Woven area only): | 4 inches |

| Thickness: | 0.03 inches (0.762mm) |

| Mass: | 610g/m² (18oz/yd²) |

| Moisture Content (%): | <0.15 |

| Weave: | Plain Weave |

Package Contents:

- 100 linear feet of Plain Weave 18oz (610g) Fiberglass Woven Roving in 4 inch width.

Share